How to Avoid Clogging of Stainless Steel Mesh?

Apr. 23, 2020

In daily life and machine production, how to effectively prevent the

stainless steel mesh from clogging is a concern of many customers. When the

nutrient content in the filtration background exceeds 5,100%, if there is no

condition for drying materials, the drying screen surface and stainless steel

screen should be selected. When the nutrient content exceeds 8 100%, a wet sieve

should be used. For materials with more flake particles, it is necessary to

change the particle size distribution of the material crushing method and

different crushing methods. As a Stainless Steel Wire Mesh Supplier, share with

you.

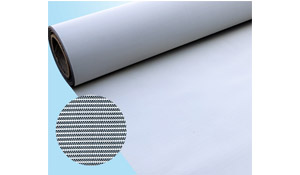

Filtrate Wire Mesh

Because most of the material particles to be screened are irregular, there are many reasons for clogging. When the particle size of the material is fine, the mud content is high, and the screening particle size is small, the resistance of nutrients to the stainless steel mesh has a voting effect. Filtrate Wire Mesh is easy to cause network congestion during use. Summarized as follows: Spherical particles are also materials with multiple contact points on the stainless steel mesh. Simply put, the clogging of the stainless steel mesh is due to the large size of the contact plane or the surface of the object and the large number of contact points.

The impurities in the filter material are crowded and are rich in particles near the mesh volume of the stainless steel mesh. A simple understanding is that the diameter volume of the filter is almost the same as the volume of the stainless steel mesh, so it is easy to clog the mesh fiber quality material; there are many flake particles; congestion in the manufacture of stainless steel mesh; thick stainless steel mesh. They will not reach the upper and lower layers, which will cause the particles to get stuck.

A stainless steel filter cartridge is a cylindrical element used for filtering, and is generally divided into a filter cartridge for filtering a gas medium and a liquid medium. It belongs to the surface filter element, which uses the fine ventilation arrangement formed by the surface of the filter material to block the particulate matter in the gas.

The advantages of the filter cartridge: the filter area is added 3-5 times, the filter wind speed is greatly reduced, and the dust removal rate is increased by 99.99%. The length of the filter cartridge is short, and there is a large remaining space, which is conducive to dust settlement and the life of the filter cartridge is extended. Venturi tubes and cages are all cleared. The filter element is short and few, easy to install (top mounted), easy to repair and replace.

The application scope of filter cartridges: petrochemical high-temperature gas filtration, catalytic cracking oil slurry filtration catalyst filtration and separation; metallurgical high-temperature flue gas purification; other high-temperature gas and liquid filtration; used in high-pressure backwash oil filter; oil, beverages Wait for the filtration of slurry; purify and filter sewage.

Our company also has Fine Stainless Steel Wire Mesh for sale, please contact us.