What are the Benefits of Selecting Gas Filtration SS Wire Mesh According to the Environment?

Jul. 10, 2020

As a Stainless Steel Wire Mesh Supplier, share with you. Air filtration

devices have been widely used in our lives. The high-efficiency filter and

ultra-efficient air filter are suitable for air filtration with high air

purification requirements, and can be applied to dust-free purification

workshops in the aerospace, aviation and other fields, as well as industries

such as pharmaceutical and biological engineering.

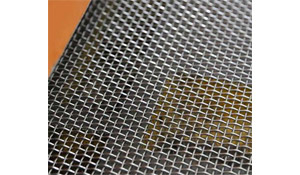

Gas Filtration SS Wire Mesh

Air filters can be divided into Gas Filtration SS Wire Mesh, air purifiers, rail transit, automobiles, ship air filters, clean room air purification equipment, etc. According to their field of application. The invention can be applied to places such as homes, office buildings, schools, automobiles, and rail transits that do not require strict air purification, such as air conditioner filters with high filtration efficiency and some air purifiers.

Due to factors such as air pollution, uncontrolled environment and the increase in the number of smokers, the incidence of lung cancer has been increasing in recent years. The public has shown unprecedented anxiety and worries about the hidden dangers caused by environmental pollution, and the environmental awareness of the whole population has been continuously improved. For the choice of buying air filters, we always choose high efficiency filters.

The high efficiency filter on the surface of the high efficiency filter is much better than the medium efficiency or primary efficiency filter. However, we must also choose according to our actual environment. For places with low environmental requirements, we can choose primary efficiency filters and secondary efficiency filters. For places with high requirements, we can also choose high-efficiency filters. The filtering effect of the high-efficiency filter can intercept the dust particles of 3UM and purify the air better.

In daily life and machine production, how to effectively prevent the stainless steel mesh from clogging is a concern of many customers. When the nutrient content in the filtration background exceeds 5,100%, if there is no condition for drying materials, the drying screen surface and stainless steel screen should be selected. When the nutrient content exceeds 8 100%, a wet sieve should be used. For materials with more flake particles, it is necessary to change the particle size distribution of the material crushing method and different crushing methods.