Why do Broken Wires Occur When Using Filtrate Wire Mesh?

Feb. 21, 2020

As a Stainless Steel Wire Mesh Supplier, share with you.

Filtrate Wire Mesh occasionally shows broken or broken wires in the process of using it. What is going on? The oil may be cut off in succession during the mold loading process, which will cause the mold to run a large distance in a short time, the shrinkage ratio will be out of balance, and then the wire will break. The treatment method is to add lubricant to each mold in time to ensure its cooling and lubrication.

When the scale adjustment of the mold is wrong, the proportion of the normal tightening ratio will be disordered during the weaving process, and the thread will be broken. The solution is to ensure the upper scale of the mold. A piece of road in the mold was consumed too quickly, which caused the imbalance of the front and back tightening ratio in the weaving, and the broken wire flashed. The solution is to transform the mold and adjust the tightening ratio before and after until it is normal.

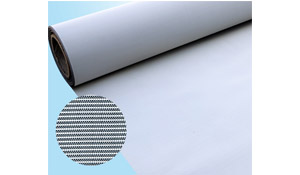

Filtrate Wire Mesh

When the wicker wire is presented during the weaving process, the stainless steel wire will be broken when the thread is taken too fast. The processing method is to transform the mold to ensure that the phenomenon of wicker silk no longer occurs. Therefore, the stainless steel wire mesh does not look very messy in structure, and it is indeed mixed with the sweat of many secret net weavers and the fine production process of technical staff. In the process of production, a variety of problems will be presented, all of which need to rely on the operation of technical staff to prevent unnecessary problems. The above are some superficial views of broken stainless steel wire.

There are many differences in the quality of filter meshes, so you need to pay attention when purchasing. So what are the differences in the quality of these products? The important thing is the difference in materials, so it will make a big difference in its application quality. In what ways can the quality of the filter mesh differ?

In addition to ensuring the firmness of the product, it has also made great progress on the surface. However, some manufacturers not only have poor welding equipment, but also are relatively backward in terms of skills, so their products will not meet the process requirements in welding. If the filter mesh is produced by a small manufacturer, it will be difficult for the artificial mesh to meet the request in terms of welding process, because their equipment and skills have not reached the request. Small manufacturers usually use brushing or spray painting for treatment, while large manufacturers use electroplating or galvanizing. The difference between the two is not just the difference in surface. Preservative capacity varies widely.

Our company also has Wire Mesh for Fiber Filtration on sale, welcome to consult.