Features and Applications of Stainless Steel Crimped Wire Mesh

Apr. 02, 2022

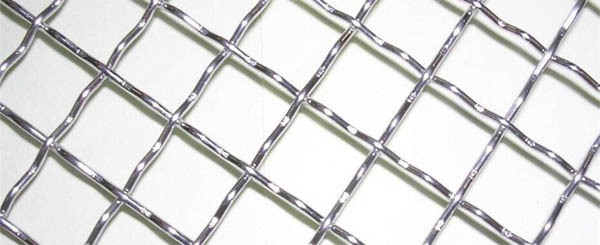

Stainless steel crimped wire mesh is crimped before weaving, and it has a strong structure, good loading capacity, and beautiful appearance.

Crimped wire mesh can serve as quarry screen, infill panel, filter element, grill, etc. And it plays an important role in the mining, chemical, petroleum, and construction industries.

Weaving Patterns:

Weaving after crimping.

In locked weave, Bi-directional plain weave, single wave weave, two-way wave weaving, rectangular opening weaving.

Features of Stainless steel crimped wire mesh:

Stainless steel crimped wire mesh is made of high-quality stainless steel wire, wire will be crimped before woven, so crimped wire mesh own stable structure, good strength, and uniform mesh. It's one of the main products of stainless steel wire mesh. And It is the best kind of decorative screen in stainless steel wire mesh. According to weave type stainless steel crimped wire mesh can be divided into plain crimped wire mesh, intermediate crimped wire mesh, lock crimped wire mesh, flat top crimped wire mesh, etc. Stainless steel crimped wire mesh can be used for withstanding shocks, squeezing, material wear, and other harsh working conditions. It can also be used as a highway fence, rail fence, residential fence, courtyard fence, etc., mainly used in building decorate mesh. And It can also be used for acid, alkali conditions screening and filtering. The main advantages of stainless steel crimped wire mesh:

● Great strength and solid structure;

● Good rust and corrosion resistance;

● High loading capacity;

● Long service life;

● High filtration accuracy;

● High compressive strength,

● High temperature, hold to chemical corrosion, Abrasion to hold;

● Good formability.

● Beautiful decorative effect.

Applications of Stainless steel crimped wire mesh:

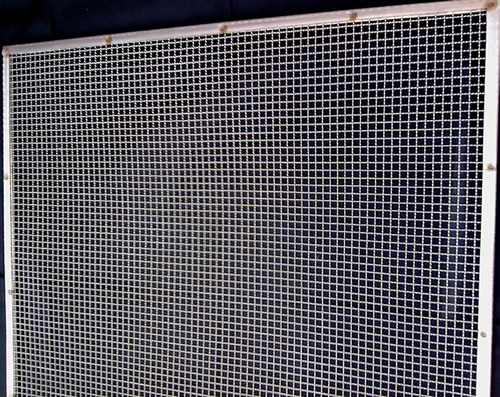

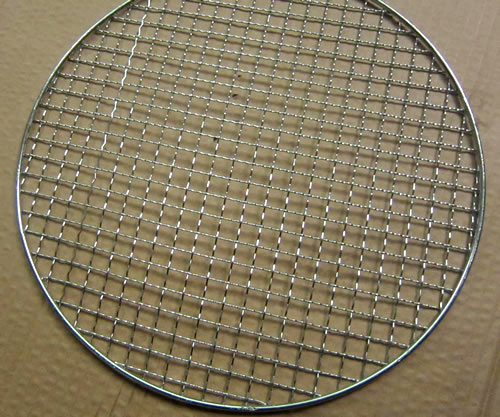

● Serves as vibrating screen, filter element, infill panel, barbecue grill, baking rack;

● Used in mining, chemical, petroleum, construction industries;

● Designed into the decoration, and artwork.

Specifications of stainless steel crimped wire mesh:

● Materials: stainless steel 301, 302, 304, 304L, 316, 316L, 321.

● Mesh width: up to 2000 mm.

● Aperture width: 10–120 mm in the case of multi-notch meshes and 4–40 mm in the case of single-notch meshes.

● Weaving method: crimped before weaving.

● Surface treatment: pickling and passivation, polishing.

● Frame:

► Cut the edges;

► Bent edges;

► Sheathed hooks.

● Packing:

► Sheets on pallets or in wooden cases;

► Rolls are wrapped with waterproof paper and plastic film.

Common Crimped Mesh Specifications

| Wire Gauge (SWG ) | Wire diameter (mm) | Mesh holes / inch | Aperture (mm) | Weight(kg) |

| 6 | 4.8 | 1 | 20.6 | 11.5 |

| 8 | 4.05 | 2 | 9 | 16.5 |

| 10 | 3.2 | 2 | 10 | 10.5 |

| 12 | 2.6 | 3 | 5.9 | 10.5 |

| 14 | 2.0 | 3 | 6.5 | 6 |

| 16 | 1.6 | 4 | 5 | 5.5 |

| 17 | 1.4 | 5 | 5.1 | 5.0 |

| 18 | 1.2 | 5 | 4 | 3.6 |

| 19 | 1.0 | 6 | 3.2 | 3.0 |

| 21 | 0.8 | 7 | 2.8 | 2.3 |

| 22 | 0.7 | 8 | 2.5 | 2 |