Will Destroying the Passive Film of Stainless Steel Wire Mesh Reduce Corrosion Resistance?

Jul. 30, 2020

As a Stainless Steel Wire Mesh Supplier, share with you. Stainless steel wire mesh has good corrosion resistance, high temperature oxidation

resistance, good low temperature performance and excellent mechanical

properties. Therefore, it is widely used in screening and filtering under acidic

and alkaline environmental conditions, chemical packaging, oil screens and other

industries. Its main purpose is to prevent corrosion and rust.

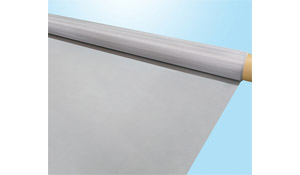

Liquid Filtration Wire Mesh

Stainless steel mesh surface oil, rust, non-metallic dirt, low melting point metal contaminants, paint, welding slag during forming, assembly, welding, weld inspection, such as flaw detection, pressure testing, and structural marking of stainless steel equipment and components, with Splash, etc., these materials will affect the surface quality of stainless steel equipment and components, destroy the oxide film on the surface, reduce the overall corrosion resistance and local corrosion resistance (including pitting corrosion, crevice corrosion) of stainless steel molds, so as to cause stress corrosion split. The surface cleaning, acid treatment and passivation treatment of the stainless steel wire mesh can not only improve the corrosion resistance to a greater degree, but also prevent product pollution and beauty.

The surface of the container made of stainless steel wire mesh and composite steel plate with anti-corrosion standards should be acid treated and passivated. This is used for filtration in the chemical and petroleum industry, because this type of machinery and equipment is used for direct contact with corrosive media. From the viewpoint of ensuring corrosion and corrosion resistance, pickling passivation must be provided. Compared with other industries (for example, for anti-corrosion purposes), stainless steel materials do not need pickling process only because of the need for cleaning and beauty. However, the butt welds of stainless steel equipment should also be pickled and passivated, and the stainless steel mesh passivation film should be repaired to improve rust resistance.

The appearance of the stainless steel filter must be maintained in time to maintain its clean appearance and prolong its service life. When washing the appearance of the stainless steel filter, pay attention to the appearance of scratches. Do not use washing liquid containing bleaching ingredients and abrasives to remove the washing liquid. After washing, wash the appearance with water.

Our company also has Liquid Filtration Wire Mesh on sale, welcome to contact us.