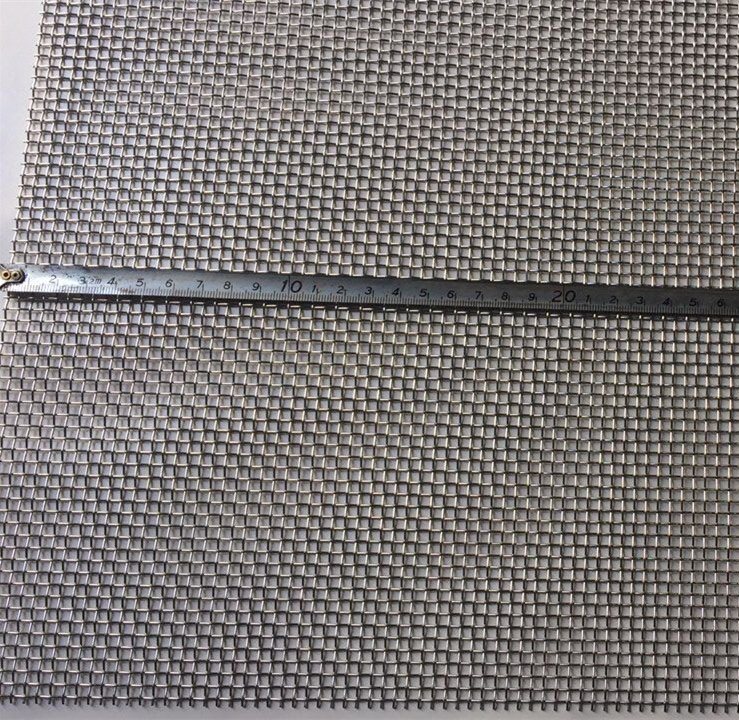

Understanding the welding process of stainless steel wire mesh

Feb. 24, 2022

Welded stainless steel wire mesh requires a high degree of precision. YKM's team has decades of experience in welding and meshing products. In this new article, we focus on the welding process of stainless steel wire mesh. Spot Welding - A good option is spot welding, which involves the use of roller electrodes to shape the wire mesh.

MIG Welding

Metal inert gas (MIG) welding effectively joins stainless steel wire and wire mesh. This process uses an arc that mixes argon and carbon dioxide to prevent contamination of the weld.

TIG Welding

TIG (tungsten inert gas shielded) welding is similar to MIG welding, but the welder uses non-consumable tungsten rods and consumable filler rods instead of self-consuming electrodes. TIG welding requires a higher level of skill than MIG welding simply because of the precision required. Some companies are now using automated TIG welding machines to streamline the process.

Silver Soldering

Many use silver soldering with stainless steel wire mesh to support optimum rigidity and durability when welding joints. The low thermal conductivity of stainless steel makes it suitable for the welding process, as molten solder is less likely to flow out of the target area.

What to consider when choosing a stainless steel wire mesh specialty

Now that you know more about your options for the wire mesh welding process, the next step is to choose a professional who can take on some of the welding work for you. Consider the following factors when evaluating service providers.

► Experience working with wire mesh

Screen welding work can be a delicate process that requires precision. Make sure your service provider has experience working with wire mesh in a variety of processes.

►Project Objectives

Make sure you evaluate the goals of your welding project with your service provider. What are your durability requirements for wire and wire mesh? What applications will the wire mesh be used for?

►Price

Due to the complexity involved in processes such as TIG welding, it can become expensive for small businesses. Before proceeding, make sure you have a budget and clear instructions on pricing. The YKM team is ready to guide you through your wire mesh welding project. To learn more about our company and services, please contact us today.