What You Need to Know About Woven and Nonwoven Mesh Fabrics

Dec. 20, 2021

Wire mesh products are the unsung heroes of our daily lives. These products are used in all aspects of life. Everything from the aerospace industry to food and beverage production relies on woven and non-woven webs. But what are the main differences between woven and non-woven wire mesh products and, more importantly, which one is right for your application? Let's take a closer look at what makes these mesh products unique and compare their advantages.

Differences in construction

The main difference between woven and non-woven wire mesh is the way they are designed. Each type of wire mesh can be made from a variety of materials, including stainless steel, and is used for a variety of industrial applications. It is also common to find woven and non-woven mesh filters working together. This is what makes each type of mesh unique.

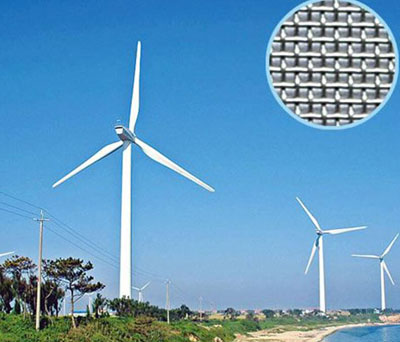

Woven Mesh

As the name implies, these baskets are made in the same way as any other woven material. Just like a knitted scarf, these mesh products are made from interwoven metal threads. The advantage of woven mesh is the ability to be made from a variety of materials because they do not need to be welded in place. This also makes them very flexible and perfect for applications that require odd shapes and contours. Woven webs are also easier, faster and cheaper to produce. They are usually supported by thicker nonwoven baskets. This allows them to perform their vital function while gaining the extra support that woven webs usually require.

What about their nonwoven counterparts?

Nonwoven fabrics

Compared to woven webs, nonwoven webs are stronger but less flexible. Nonwoven webs are usually constructed by welding metal strands together. This will create a similar mesh to woven mesh, but it has some strong advantages. Our nonwoven mesh product can be galvanized for added durability. It can also be produced with greater precision than woven products. This makes them ideal for industries with very high regulatory standards. Because of its durable construction, nonwoven mesh can hold heavier and smaller filter objects better than woven mesh.

The most significant difference is that non-woven fabrics are stronger than woven fabrics. This makes them ideal for applications with high pressures and conditions that can damage woven wire mesh.

Mesh Features and Applications

Each of these meshes has a unique application and are often used together. The flexibility and affordability of woven mesh filters make them an excellent choice for industries that require quick solutions for specific conditions. Nonwoven mesh is designed to be able to handle harsher conditions, higher holding standards, and offers a slightly more expensive rigid design than woven mesh products.

Important Points

Here's what you should know about these meshes

▴ Woven mesh is flexible and ideal for unique contours

▴ Nonwoven fabrics can be designed to tighter specifications and are more robust

▴ Our stainless steel woven wire products are rugged and can handle extreme conditions

Both woven and non-woven fabrics offer unique and important features for every industry.

Previous: Getting Started with Wire Mesh