Why is a sprinkler installed with a filter?

Dec. 02, 2019

Does Liquid Filtration Wire Mesh play a large role in actual use? Let's talk about the actual cases around us first. Many friends report that the water volume will decrease after the sprinkler is used for a period of time. After communication, it was discovered that the user did not know that there was a filter at the water inlet.

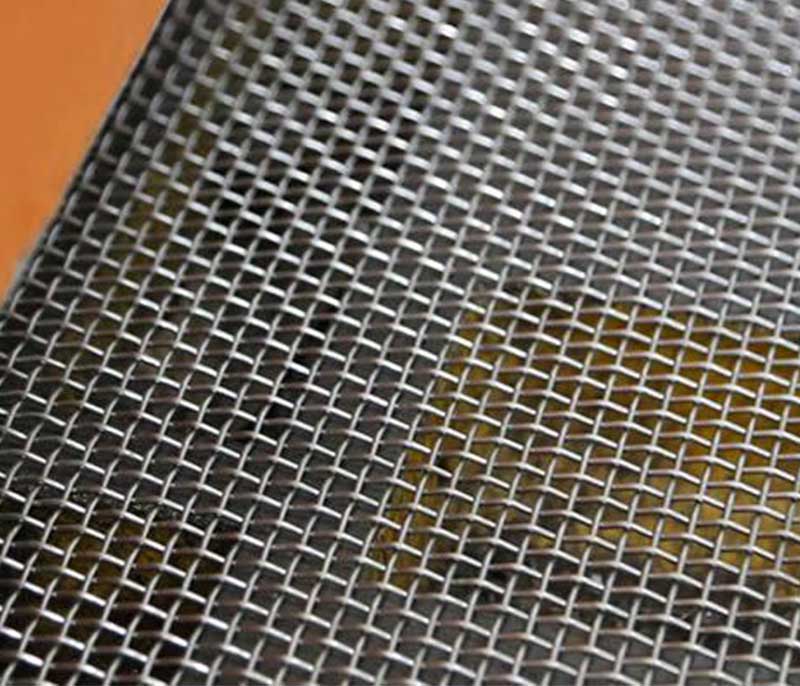

Custom Stainless Steel Wire Mesh

A cylindrical filter is installed at the water inlet of the sprinkler, but what does the filter of the sprinkler do? In fact, the final reason for the above phenomenon is that the filter is not cleaned in time. When the sanitation sprinkler uses a sprinkler pump to absorb water, the water source may be a variety of water sources such as ponds, weir ponds, reservoirs, etc. These water sources are not filtered and may be mixed with debris such as branches, weeds, etc. When the water source enters the pipeline, water pump and water tank through the water inlet, it may cause a blockage. Even after entering the tank body smoothly, during the drainage process, the outlet pipe and pump may be blocked. It is also impossible to discharge smoothly after spraying. No matter where the blockage occurs, it is very difficult to handle. Therefore, the designer of the sanitation sprinkler truck installed a cylindrical filter at the water inlet, which can effectively reduce the occurrence of clogging. However, after the filter is installed, if the unfiltered water source is often used, the filter must be cleaned in time, if the water is not cleaned in time, the water volume will decrease. When the filter is not cleaned for a long time, the filter screen may be ruptured or damaged if it is subjected to a certain pressure of water under the condition of blockage. Therefore, the sanitation sprinkler filter is an important part of this type of vehicle maintenance. Normal maintenance can significantly increase the service life of sanitation sprinklers.

Stainless steel screen storage environment is very important

Custom Stainless Steel Wire Mesh is a corrosion-resistant steel wire, which is not absolutely non-rusty, and the corrosion performance in chemical media is not particularly stable. The corrosion resistance of stainless steel wire mesh is affected by its chemical elements nickel, chromium, copper, molybdenum, titanium, niobium and nitrogen. The purchase of stainless steel screens must consider the material of stainless steel screens because the use of stainless steel screens has high requirements on their structure and performance. In addition to the storage environment of these stainless steel screens, it is also important. The following explains our factory Storage requirements for stainless steel screens.

Stainless steel screen storage environment is very important

1. The stainless steel screen warehouse needs to be kept ventilated, dry and clean, and avoid direct sunlight;

2. In case of severe weather, take protective measures to prevent the stainless steel screen products from being affected by rain and snow.

3. Pack the stainless steel screen, and avoid contact with acids, alkalis, oils, organic solvents and other substances;

4. The stainless steel screen products should be sorted and placed in rolls, and they should be turned once every quarter.

5. The temperature and humidity of the storeroom should be controlled at 25 ° C and 50 ° C.

6. If any problem is found in any link, it must be resolved quickly.

We are Stainless Steel Wire Mesh Supplier, welcome to consult.